In the world of modified plastics, unbalanced material performance often becomes a bottleneck for product upgrades — strong impact resistance may lead to hazy coloration; eye-catching appearance might fail to meet moisture-heat impact requirements. That’s where KINGFOX Impact Modifier USI-3310 comes in as the "Master of Balance," engineered to solve this dilemma.

From precision electronic enclosures to outdoor equipment, no matter how harsh the application scenario, it enables simultaneous enhancement of impact resistance and color performance, truly achieving "no compromise" across coloration, moisture-heat resistance, weather resistance, impact resistance, and chemical resistance. Next, a set of actual test data will unveil the performance indicators of KINGFOX USI-3310. For more measured data, please contact your dedicated sales consultant!

Moisture-heat resistance 95℃ 95%RH

Temp/ humidity /duration | ITEM | Industry standard | PC | PC +5%USI 3310 |

| 25℃ | MFR | GB/T 3682 [g/10min] | 9.31 | 8.15 |

| IZOD | ASTM D256 [J/m] | 864 | 755 | |

168h 95℃ * 95%RH | MFR | GB/T 3682 [g/10min] | >80 | 9.7 |

| IZOD | ASTM D256 [J/m] | 58 | 745 | |

| retention rate | 6.7% | 98.6% | ||

336h 95℃ * 95%RH | MFR | GB/T 3682 [g/10min] | >80 | 14.36 |

| IZOD | ASTM D256 [J/m] | 10 | 659 | |

| retention rate | 1.2% | 87.3% | ||

504h 95℃ * 95%RH | MFR | GB/T 3682 [g/10min] | >80 | 25.04 |

| IZOD | ASTM D256 [J/m] | 0 | 518 | |

| retention rate | 0 | 68.6% |

High temperature resistance Heat retention 15 min-pass

| Impact Modification | Kingfox USI-3310 | competitor | |

| ITEM | Industry standard | CS-4566 | CS-4569 |

| MFR[g/10min] | GB/T 3682 [g/10min] | 8.5 | 8.9 |

| IZOD -30℃/4h | ASTM D256 [J/m] | 336 | 285 |

| IZOD 25℃ | ASTM D256 [J/m] | 806 | 801 |

| Tensile Strength[Mpa] | ASTM D638 | 65.6 | 66.6 |

| Elongation at Break[%] | ASTM D638 | 142 | 148 |

| Flexural Strength[Mpa] | ASTM D790 | 88.6 | 88.6 |

| Flexural Modulus[Mpa] | ASTM D790 | 2198 | 2202 |

| L Level | 29.45 | 29.36 | |

| Heat Retention Test | 300℃ injection molding tempt. 100℃ Mold tempt | 15min-PASS | 10min-PASS |

20min-NG (water mark) | 15min-NG (water mark) | ||

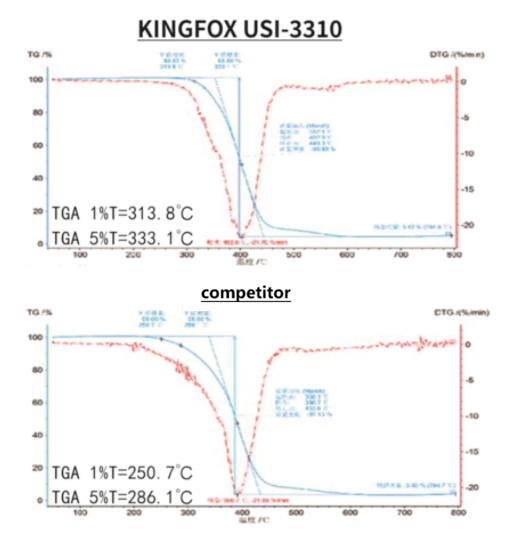

Thermogravimetric Analysis TGA 1% 5%

Founded in 2008, EVERSUN Co., Ltd. specializes in R&D and production of PC flame retardants, PC Impact Modification, anti-dripping agents (PTFE-based and fluorine-free), compatibilizers, plastic processing stabilizers, and more. With an annual production capacity of 35,000 tons and nearly 20 years of experience in providing PC modification solutions, we welcome inquiries and technical exchanges!

Previous:How to achieve UL94 V-0 rating for 1.5mm thick PC flame-retardant material?

Next:DOW FCA-107 cannot meet PFAS regulations. Are there any alternatives?